The U.S. Department of Agriculture said it has fired 70 foreign contract researchers after a...

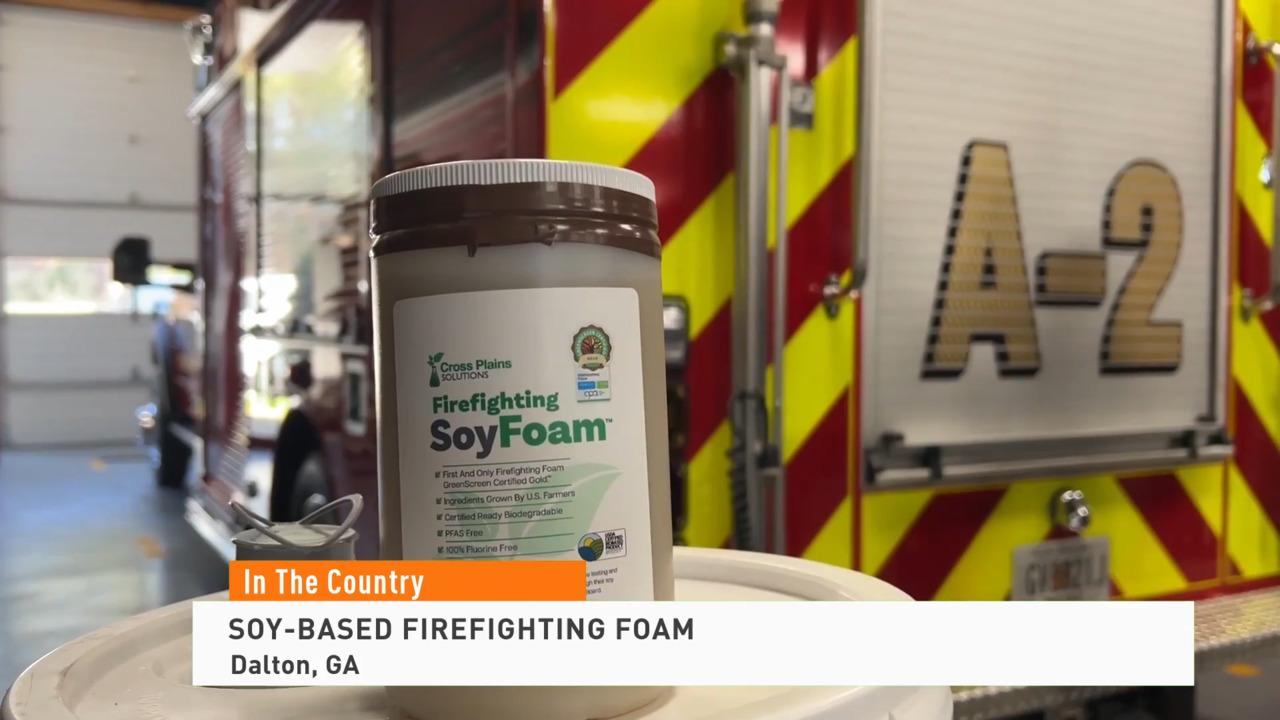

From Farm to Fire: First Soy-based Fire Suppressant Hits the Market

A new soy-based fire suppressant has hit commercial scale and its due in part to research funded by U.S. soybean farmers.

Cross Plains Solutions developed SoyFoam, the first and only soy-based firefighting foam. Managing Partner Alan Snipes says, "It is a safer product than anything that’s out on the market right now. We’ve just been certified Green Screen Gold certification."

That’s because SoyFoam is free of PFAS or forever chemicals, with no detectable flourines found in conventional fire suppressants.

Neal Bredehoeft, Director on the United Soybean Board says, "In the past there have been some cases of firefighters dying or contracting cancer because of the harmful chemicals in the foams they’ve been using."

Dave Garlie worked in the lab to help develop Soyfoam, which is 84% biobased. "It's something that is more environmentally friendly, that’s healthier, that’s safer for use and then after point of use it’s rapidly degradable. It leaves no environmental footprint."

Snipes says even though the product is green, its price competitive with conventional firefighting foams. "Right now, based on what the market is, we see that we are comparable in price and in some cases even cheaper."

It’s also a sustainable solution as it’s made from 50% soybean meal or flour. A new use and market opportunity needed for the extra meal that will come with soy processing expansion.

David Struck, Chairman of the South Dakota Soybean Research and Promotion Council says, "A lot of the oil stock is going for renewables and biofuels and so we’re getting a lot of meal and if we can use it domestically that’s a huge shot in the arm for us."

Through the soy checkoff soybean, farmers funded research and extensive testing for Soyfoam, according to Bredehoeft. "It is a new product that we can use with soybean meal and that’s one thing the United Soybean Board has started to focus on is how do we start to make new products out of soybean meal we’re going to have in the future because we can only utilize so much with livestock."

Premier Polymers in Dalton, Georgia, will be manufacturing SoyFoam. Business Manager Scott Hanson says they’re seeing an industry shift toward biobased products. "We see this push to get away from PFAS and so we’re eager to be involved in anything that separates us from that."

Soyfoam….a new use going from farm to fire.

EDITOR’S TAKE:

The United Soybean Board, charged with overseeing the investment of soy producer check-off dollars, has been very instrumental in the development of several new soy-based products in recent years. SoyFoam is merely the latest example. It uses a sustainable product (soybean meal), leaves no environmental footprint and is often less expensive than conventional products. This sure sounds like a win-win-win situation. A win for soybean farmers. A win for fire-fighters. And a win for the environment. Congratulations all around on the creation of another out-of-the-box product. Make sure you are also thinking outside of the box. How can you leverage your fixed ops, parts and service departments, to attract farmers/ranchers to use more of your products versus letting that business go to NAPA or similar retailers. Maybe you create a parts-service agreement with farmers/ranchers in your area. I’m sure you can think of a number of ideas once you start to brainstorm with your employees.